Establishment of Membrane Technologies Ltd - Now Membrane Hitec (MHT), Chennai, India

Successful research carried out by MRTS on "made in Singapore Ultrafiltration membrane" was then synergized with the establishment of its 100% owned – Membrane Technologies Ltd, in the year 1998, with technology transfer to the regional Company with repatriation benefits. The Company, on a war-footing, rigged up the infrastructure and started the commercial production in March 1999. It also received good guidance and support from membrane Scientists from Europe, USA, Australia and India.

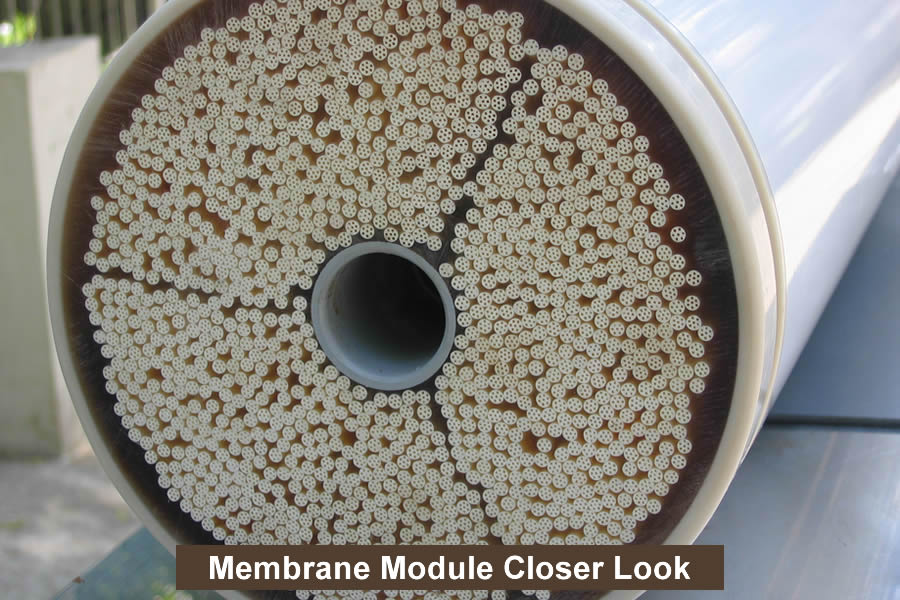

Membrane Hitec spins Capillary type ultrafiltration membranes, out of various polymers and manufactures modules and systems for wide range of applications - safe and bacteria free drinking water, waste water/ sewage water treatment, pre-treatment to sea water.

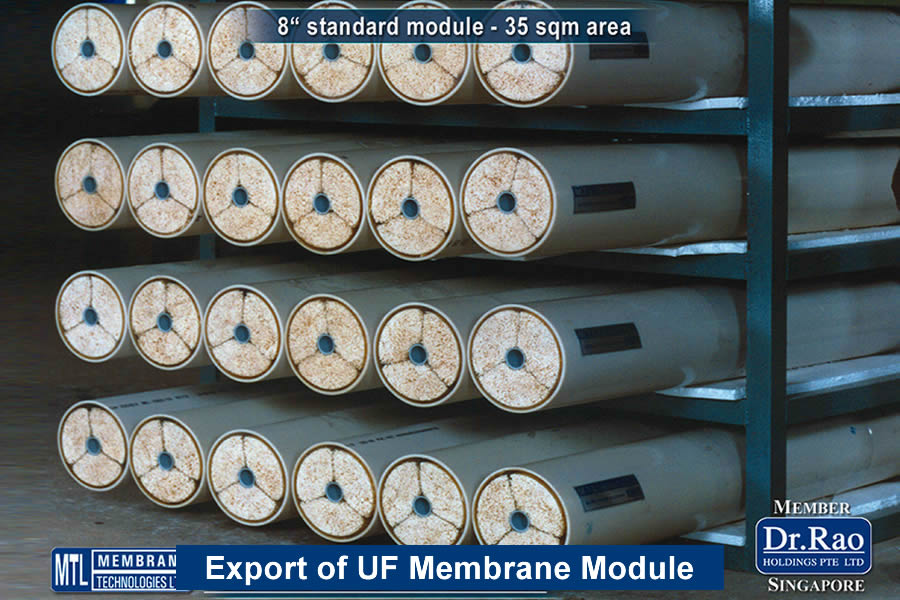

Exports

Membrane, membrane modules and systems have been exported to various countries like, USA, Europe, Australia, Singapore, South Africa and so on, besides India. The quality, has been on par with other leading membrane manufacturers in the World. Consequently, MHT has been getting repeat orders.

The membranes are tailored for a particular application, maximizing the flux and rejection characteristics, both for industry as well as home. It also employs membrane process for various un-explored areas.

Global Market

MRTS, effectively demonstrated as a trailblazer in the area of membrane technology and products, and earned the attention and confidence of multinational Companies such as Dupont, USA for global marketing UF membrane system for hot brine concentration in chlor alkali industry and with Chemetics Inc. Canada, for Sulphate Removal Technology, for manufacturing their systems.

The mission of MRTS is increased participation in Singapore’s technology, innovation and economic growth through promotion of greater cooperation between Singapore and other countries, in the near and longer terms.

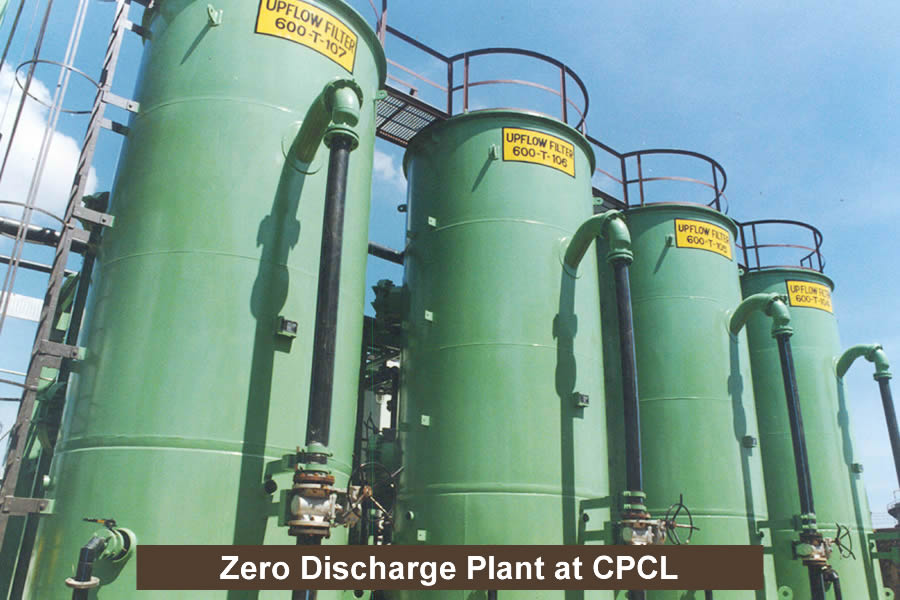

Pilot Plant at CPCL

Chennai Petroleum Corpn Ltd (CPCL), one of the leading biggest refineries in Chennai, South India, is always in the fore-front in introducing newer technologies.

When MHT approached, CPCL, after various presentations and appeal, agreed for MHT putting up a pilot plant at the risk and cost of MHT, to treat both Tertiary Treated Water and Effluent water. MHT took up the challenge and technically and commercially proved UF technology is the best for treating both type of water.

After 18 months of pilot run and testing by CPCL technical team and having convinced on the efficacy of UF membrane technology of MHT, CPCL decided to award ON NOMINATION BASIS, a contract for treating nearly one million gallons per day capacity, within a very short period. MHT gave a competitive proposal with a pay back period of just 15 months.

One Mgd (approx) Zero Discharge Plant - For CPCL - First In India.

Within five months (much ahead of the contract schedule of 9 months), MHT, put up the plant at CPCL in 2001, replacing all the conventional pollution – prone chemical technologies. The Operation and Maintenance contract also was awarded to MHT.

MHT incorporated various innovative designs in this plant to make it compact, easy for operation and maintenance, with very high performance and all controlled by PLC.

The success of this plant, paved the way for CPCL to go in for higher capacities.

Development of 16" Dia Membrane Module

With the urge to develop membrane modules of higher area, MHT successfully developed, upgrading the standard / conventional sizes, membrane module of 16” dia with membrane surface area of 120 sqm unlike standard area of 35 sqm.

These membrane modules are working very well, in the treatment of hot brine in our chlor – alkali plant.

MHT has also developed "out-to-in" membranes, which is the cutting edge technology, with more membrane surface area, compared to "in-to-out" configuration. However, this can be used for specific applications only.

For more information, please visit : Website www.membranehitec.com, to know about the salient features of MHT membrane and its modules.